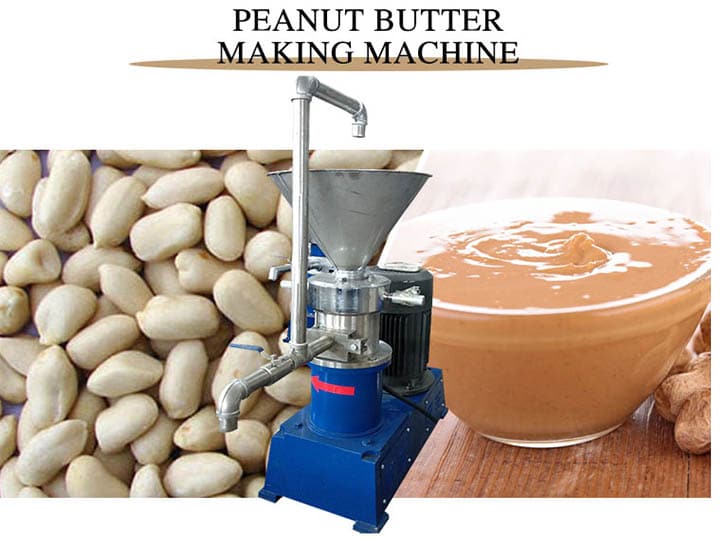

Peanut butter making machine, or peanut butter grinder machine is widely used in the food industry, especially for peanut, rapeseed, sunflower seeds, sesame, cocoa beans, almonds etc. The peanut butter grinder is an advanced and multi-functional grinder, which can be used to make peanut butter, almond butter, walnut butter and other nut butter. In addition, the best peanut butter milling machine applies to the pharmaceutical industry, chemical industry and other industries.

Peanut butter making machine structure and working principle

The peanut butter grinding machinery is mainly composed of a core part, a basic transmission part and a dedicated motor. Dynamic grinding and static grinding of the core components are key components of the machine, so the choice may vary depending on the nature of the material being processed. In addition to the motor and parts, the parts in contact with the material are high-quality stainless steel, including the critical moving and static grinding discs. Therefore, the peanut butter grinder has good corrosion resistance and wear resistance, making the processed materials clean and hygienic.

There are two wheels inside peanut butter making machine, one is fixed and the other one has rotating motions. The gap between the wheels is adjustable. After raw material enters the feeding port, the fixed wheel of the machine rotates to grind and crush the material to achieve the ideal effect. The raw materials rub back and forth between the two wheels in operation. Under centrifugal force, the original materials become the sauce.

Cautions and operation of butter grinder machine

1. Check whether there are hard materials such as stones, broken glass and metal shavings mixed into the raw materials. Screening the materials to avoid damage to the machine.

2. It is not allowed to idle and reverse the peanut butter making machine. Water or liquid material must be left in the body of the machine before starting. Because improper handling can severely damage mechanical parts, grinding discs, or the motor.

3. In operation, once the machine suddenly makes a lot of noise in work, stop the bearing immediately, and check if the motor is faulty, or the fastener is loose, etc.

4. When the peanut butter colloid mill is running, do not close the drain valve to avoid leakage due to excessive pressure in the grinding chamber.

5. After using the peanut grinder machine, clean the machine body thoroughly, so that the material does not stay in the body, and there is no mechanical bonding and damage to the machine.

Advantage of peanut grinder machine

1. Space-saving and energy-saving

2. Reasonable design and stable performance

3. Easy to operate and maintain

4. High capacity and multiple models for option

5. Hygienic. Stainless steel material

5. Wide application: peanut butter making machine can be used in food processing industry, chemical industry, pharmaceutical industry, construction industry, and other industries.

Parameter of peanut butter grinding machine

| Model | SL-50 | SL-80 | SL-130 | SL-180 | SL-240 | |

| Final size of products | 2-50 | |||||

| Capacity ( t/h) | 0.005-0.03 | 0.1-0.5 | 0.4-2.0 | 0.8-6.0 | 1.0-8.0 | |

| motor | Motor power (kw) | 1.1 | 4 | 11 | 18.5/22 | 37/45 |

| Voltage(v) | 220/380 | 380 | 380 | 380 | 380 | |

| Rotary speed( r/min) | 2820 | 2890 | 2930 | 2930 | 2970 | |

| Rotor diameter(mm) | 50 | 80 | 130 | 180 | 240 | |

| Dimension | Length mm | 520 | 685 | 975 | 981 | 1319 |

| Width mm | 250 | 335 | 456 | 476 | 500 | |

| Height mm | 555 | 928 | 1054 | 1124 | 1276 | |

| Weight (kg) | 70 | 210 | 400 | 420 | 1000 | |

Our company is committed to designing and producing the highest quality peanut butter making machine for many years. Our machine has been exported to India, Canada, Thailand, Pakistan and many other countries and regions. For more information about the best peanut butter colloid mill, welcome to contact us directly.