The peanut coating machine is an important part of the coated peanut production line. The nut coating machine can coat roasted peanuts, beans, or pills with sugar or other materials. Common types are spherical pots and flat pans. Coated peanut machine is popular in the pharmaceutical and food industries. Peanuts nut coating machine wraps roasted and peeled peanuts in a layer of syrup, flour, glutinous rice flour, etc.

There are two different processing methods for coated peanuts: one is frying and the other is roasting. The roasted coated peanuts have bright colors, a smooth surface, and a uniform thickness of the coating layer.

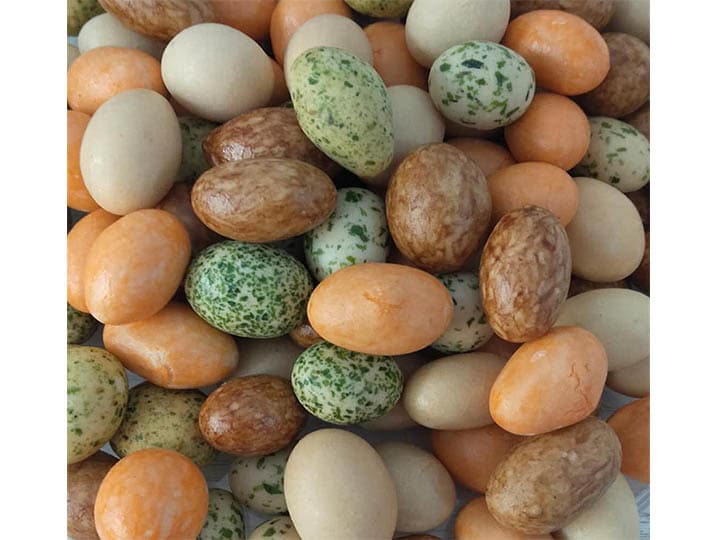

The coated peanut machine can make peanut burgers, flour-coated peanuts, fish skin-coated peanuts, chocolate-coated peanuts, multi-flavor peanuts, Japanese-style coated peanuts, candied peanuts, etc. Our peanut burger machine has been popular in many countries, including Nigeria, Kenya, India, etc.

Peanut coating machine features

- High production efficiency and large output: 150-200 kg/h.

- The adjustable tilt angle of the pot or pan (15-95 degrees).

- Uniform thickness of the coating and good color.

- Different heating methods: electricity or gas.

- Multiple options: different diameters (400-1200 mm) and capacities available.

Peanut flour coating equipment structure

The peanut coating machinery contains the main body, gearbox, pot, heating device, fan, electric appliance, etc. This coated peanut machine is made of stainless steel. The coating machine for peanuts has the characteristics of stable rotation, low noise, no pollution, etc.

Working principle of peanuts burger machine

The flour-coated peanut machine is driven by the motor to rotate the pot, and the material smoothly rolls up and down in the pot to get coated. The coated peanut machine can be heated by electricity or gas and equipped with a blower, a spraying gun, and an air compressor.

Parameters of peanut coating machine

| Model | TZ-400 | TZ-600 | TZ-800 | TZ-1000 | TZ-1200 |

| Dimension(m) | 0.8*0.4*1.2 | 0.9*0.6*1.2 | 1*0.8*1.2 | 1.2*1*1.3 | 1.3*1.3*1.3 |

| Capacity (KG) | 30 | 30-60 | 50-100 | 70-150 | |

| Diameter(mm) | 400 | 600 | 800 | 1000 | 1200 |

| Angle of pot | 15-95 | 15-95 | 15-95 | 15-95 | 15–95 |

| Main motor power (KW) | 0.75 | 0.75 | 1.1 | 1.1 | 1.1 |

| Heating wire power (KW) | 1000 | 1000 | 1000*2 | 1000*2 | |

| Batch feeding quantity | 3kg | 10-15kg | 15-50kg | 50-70kg | 75-120kg |

Coated peanut production line

Roasted-coated peanuts and frying-coated peanuts are all popular snacks among people. The processing procedures differ in heating methods. Peanuts with a roasted coating have a smooth look and a sharp flavor, while fried-coated peanuts characterize by a frosted texture and distinct flavor.

1. Roasted-coated peanut production line

- Peanut roasting machine→ peanut peeling machine→ peanut coating machine→ swing oven→ cooling machine→ seasoning machine→ packaging machine

2. Frying-coated peanut production line

- Peanut roasting machine→ peanut peeling machine→ coating machine→ frying machine→ deoiling machine→ seasoning machine→ packaging machine