To pack the final products in a peanut butter production line, a peanut butter filling machine and other peanut butter packaging machines are commonly used. How does a peanut butter filler machine work? What machines are needed to pack peanut butter automatically? As an experienced automatic butter packing machine producer, we provide an efficient solution for butter packing.

glass jars

peanut butter and filled peanut butter

packed peanut butter with labels

Introduction to automatic butter packing machine

The automatic butter packing line includes a bottle unscrambler, filling machine, capping machine, and labeling machine. The automatic filling and packaging line is applicable to daily chemicals, oil, and other industries. The specific filling materials include sesame paste/tahini, tomato sauce, jelly, jam, chili sauce, and edible oil, etc. Among the fully automatic butter packing machines, a bottle unscrambler lines up the empty bottles or other containers like cans, jars, stand-up bags, and send them to the filling machine. After filling, the bottle will automatically move to the capping, and labeling equipment.

bottle unscrambler

automatic butter packing machine

Automatic peanut butter filling machine

An automatic piston peanut butter filling machine is an important part of the automatic butter packing machines. It is a high-precision quantitative liquid filling machine, which can fill different high-viscosity fluids. The machine has the features of compact and reasonable design, a simple and beautiful appearance, and convenient adjustment of filling volume. The butter filling machine is easy to operate, adjust, clean, and maintain. The machine can be applied to a variety of bottle shapes, such as plastic bottles, cans, glass bottles, etc.

Highlights of peanut butter filling machine

- Wide application. The automatic peanut butter filling machine applies to liquid and paste filling, such as butter, sauce, jam, cream, shampoo, liquid soap, lubricant, engine oil products.

- Adjustable filling volume and high filling precision. The filling machine adopts volumetric piston pump, and pneumatic control. The general filling volume can be adjusted from 500 to 3000ml. The error rates is very low, ≤±1%.

- Multiple filling heads for options. We provide filling machines of different heads to meet specific needs. The common types are 2-head, 4-head, 6-head, 12-head types.

- No overflow and dripping. There is an auto filling nozzle, which can ensure no overflow. Besides, the filling mouth has a tray collector under filling nozzle to avoid dripping.

- Uniform and controllable speed.

- Convenient to clean and change containers of other shapes or size.

4-head filling machine

butter filling machine

Technical data

| Filling type | Piston Quantitative Filling |

| Filling capacity | 2 heads:240KG-960KG |

| Filling capacity | 4 heads:480KG-1920KG |

| Hopper volume | 350L |

| Filling volume | 500-3000ml |

| Filling accuracy | Error≤±1% |

| Material | Stainless Steel |

| Power | 220V/50Hz, 500W |

| Air consumption | 200-300L/min |

| Machine size | 1850mm*1040mm*1900mm |

| Weight | 700KG |

Apart from automatic peanut butter filling machine, we also supply semi-automatic peanut butter filling machine. It requires receiving materials manually with containers.

Capping machine

In the butter packing line, a capping machine comes after the filling machines. The containers of peanut butter automatically move to the capping machine. This automatic capping machine connects with the filling machine and labeling machine. It is suitable for caps of different shapes and sizes. Equipped with a positioning device, it can press and twist the caps correctly. The gentle movement of the machine can avoid scratches and injury to caps and containers.

Specification of automatic capping machine

| Model | PC-200 |

| Production | 1000-2000 bottles/h |

| Power | 220V 0.8KW |

| Cap height | 10-30mm |

| Cap diameter | 19-55mm (customizable) |

| Bottle height | 80-350mm |

| Bottle diameter | 35-100mm (customizable) ) |

| Air supply | 0.4-0.6Mpa |

| Weight | 300Kg |

| Dimension | 2000*1100*1550mm |

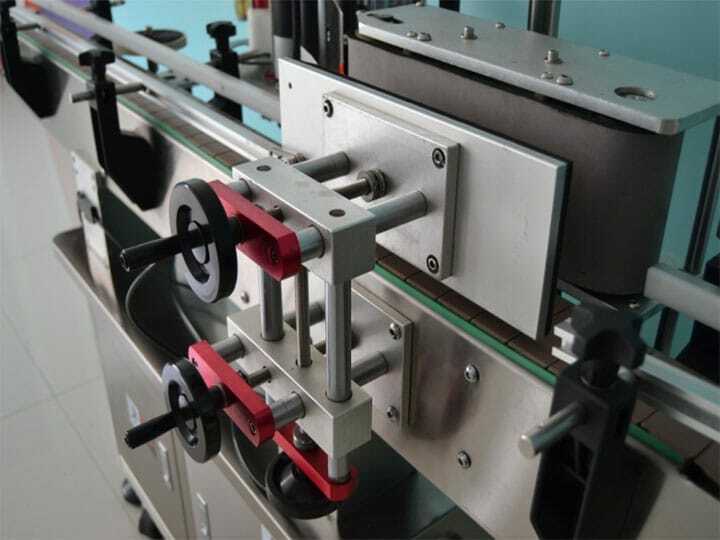

Fully automatic labeling machine

The automatic labeling machine is widely used in the labeling of plastic bottles, glass bottles, cans, jars, etc. in the food, pharmaceutical, cosmetic and other industries. It is the final equipment of the automatic butter packing machine.

Working Process

The sensor can detect the containers first and send the signal to the labeling control system. Then the control system drives the motor to send labels and completes the labeling action.

labeling machine details

labeling machine detail

Part of parameters

The following is the parameter of one model. We also have other different models and types. Besides, special needs and functions can be customized.

| Label Length (mm) | 20~314mm |

| Label width | 15~120mm |

| Conveyor speed | 5 ~ 25m/min |

| Power | 530W |

| Dimensions | 1800×800×1500mm |

We would like to receive your comments and requirements if you are interested in this automatic butter packing machine.