The fully automatic peanut butter manufacturing line is an ideal solution for the continuous production of large quantities of peanut butter. The capacity of the peanut butter manufacturing equipment reaches 500kg-1000kg/h.

Thus, the peanut butter processing line is suitable for medium or large-sized peanut butter processing factories. The main equipment of the automatic peanut butter manufacturing line involves a continuous roasting & cooling machine, a peanut peeling and splitting machine, a peanut grinding machine, and a full-automatic peanut butter filling machine.

Wide range of applications

The high-quality peanut butter produced on our production lines extends beyond retail products sold directly on store shelves.

Retail products:

- Classic spreads: we produce smooth and chunky peanut butter in various bottles and jar sizes, supplied directly to supermarkets and households.

- Flavored peanut butter: easily incorporate ingredients like cocoa, honey, and chia seeds to develop innovative flavor profiles.

Industrial ingredients:

- Baking industry:

- Serves as a rich filling or coating for peanut butter cookies, cakes, breads, and assorted pastries.

- Confectionery manufacturing:

- Serves as a core ingredient in nougat, chocolate bars, energy bars, and assorted candies.

- Ice Cream and beverages:

- Provides a peanut flavor base for ice cream, milkshakes, smoothies, and coffee.

- Sauce applications:

- Key ingredient for Asian-style satay sauces, cold noodle dressings, hot pot dips, and various compound sauces.

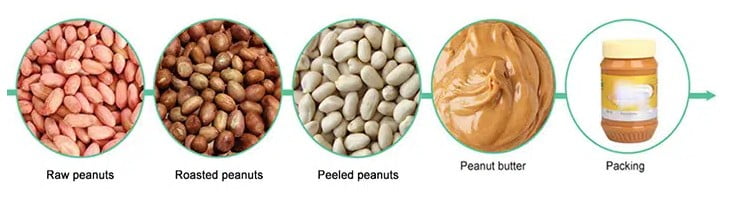

Peanut butter manufacturing process

The main peanut butter manufacturing process includes roasting and cooling, peeling, grinding, and filling.

1. Roasting and cooling

The continuous peanut roasting machine roasts the peanuts on the chain plate through hot air and then cools them down after roasting.

2. Peeling

The peanut peeling machine efficiently removes the red skins of peanuts and discharges the peeled peanut kernels.

3. Grinding

The peanut butter grinding machine is a combined peanut grinder in which the peanuts are well ground by friction, vibration, and other complex forces.

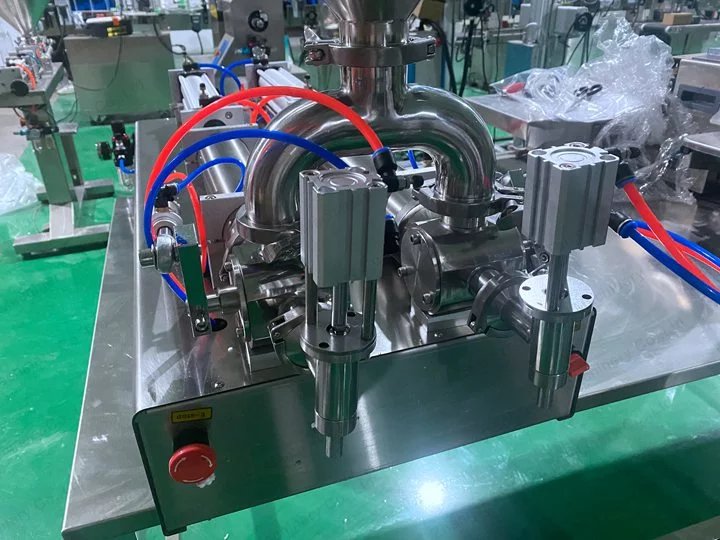

4. Filling

The automatic peanut butter filling machine has several filling heads, which fill the peanut butter with the same volume into various containers.

Features of the automatic peanut butter manufacturing line

- High degree of automation: automatic control and easy operation

- High productivity and continuous production: output reaching 500-1200kg/h

- Super-fine peanut butter and natural flavor: The fineness is as high as 125-150meshes.

- Wide application: applicable to sesame butter, chilli sauce, cocoa paste, almond butter, etc.

- Customized service available

Main technical data

The following are the main parameters of major machines and supportive equipment in the peanut butter manufacturing line.

| Order number | All machine names | Power(kw) | Dimension(mm) | Weight(kg) |

| 1 | Hoist | 0.75 | 1600x750x3000 | 260 |

| 2 | Continuous roasting machine | 130 | 8500x1800x2600 | 3000 |

| 3 | Hoist | 0.75 | 900x750x3000 | 260 |

| 4 | Peanut peeling machine | 3 | 1900*800*1350 | 500 |

| 5 | Selection conveyor | 0.75 | 6000*800*1000 | 400 |

| 6 | Hoist | 0.75 | 900x750x3800 | 260 |

| 7 | Storage device | 0.04 | 1200x1100x3300 | 200 |

| 8 | Peanut grinder machine | 30×2 | 1400x1250x2000 | 1300 |

| 9 | Storage device | 1300x1300x900(500L) | 50 | |

| 10 | Mixing tank | 3 | 1000x1000x1900(500L) | 200 |

| 11 | Degassing tank | 3+1.5 | 900x900x2500(500L) | 300 |

| 12 | Pump | 1.5×3 | 1200x300x350 | 60×3 |

| 13 | Storage tank | 900x900x1200(500L) | 150 | |

| 14 | Filling machine | 0.8 | 2000*1100*1550mm | 300Kg |

If you’re interested in our peanut butter production line after reading this, contact us today for more detailed information!

Why choose Taizy’s 500kg/h peanut butter manufacturing line?

Highly automated: the entire line requires only 2-4 workers for smooth operation, significantly reducing labor costs. It eliminates human operational errors, ensuring continuous and stable production.

Multi-purpose machine: this production line isn’t limited to peanut butter. With simple adjustments, it can produce various high-value nut butters. It helps you easily expand your product line and seize more market opportunities.

Hygienic and safe: constructed entirely from SUS304 stainless steel, the line complies with GMP and other food production standards. Its design eliminates sanitation blind spots and facilitates easy cleaning and maintenance.

Customized and flexible configuration: we tailor the production line to your specific requirements—such as whether chunky texture is needed, factory layout, or energy type. For instance, adding a nut crusher enables chunky peanut butter production, ensuring the solution perfectly aligns with your business needs.

Peanut butter production line price

We are often asked, “How much does a peanut butter production line cost?” This is an important question, but the answer isn’t a fixed figure. That’s because we don’t offer standardized products—we provide solutions tailored to your unique requirements.

The final price of the production line depends on several key factors, ensuring every penny of your investment is well spent.

Primary factors influencing production line pricing include:

Production capacity:

Do you require a small-scale line at 100kg/h, or equipment capable of 500kg/h, 1000kg/h, or even higher output? Greater capacity necessitates larger equipment dimensions, higher motor power, and increased material consumption, resulting in a higher price.

Degree of automation:

Do you prefer a semi-automated line to save on initial investment, or a fully automated line to maximize efficiency and reduce labor? Higher automation levels mean more advanced control systems and lower long-term operating costs.

Machine configuration:

Do you require additional equipment for producing chunky peanut butter?

Do you need vacuum degassing tanks to extend shelf life and enhance product appearance?

What are your specific requirements for downstream filling and packaging equipment (bottling, bagging, fully automated labeling, etc.)? Each functional module selected will impact the final quotation.

FAQ

Can this production line simultaneously produce both smooth and chunky peanut butter?

Yes. We can easily switch between producing smooth and chunky products by simply adding a nut crusher to the line.

I’m just starting. Are there smaller capacity options than 500kg/h?

Certainly. We offer multiple capacity options ranging from 100kg/h to 2000kg/h, which can be customized to your needs.

Can it produce nut butters other than peanut butter?

Yes. This versatile production line is equally suitable for manufacturing almond butter, sesame paste, and other nut butters with simple parameter adjustments.

Get your precise quote

We believe the best investment is the one that best fits your business. Rather than providing a vague price range, we prefer to gain a deep understanding of your project.

Contact our expert team today and share your ideas. We will provide you with a free, detailed, cost-effective technical solution and a customized quote!