The coated peanut making machine is mainly suitable for rolling, mixing, and polishing spherical or granular materials in the food, chemical industry, and pharmaceutical industries. The peanut burger production machine is widely used for coating and roasting peanuts, green beans, broad beans, soybeans, and other nut kernels, beans, and seeds. The common products are flour-coated peanut, peanut burgers, chocolate-coated peanuts, sugared peanuts. The coated peanut machine (also known as coated peanut production line) realizes automatic production, simple operation, labor-saving, and stable product quality. The full peanut coating machinery mainly includes a groundnut roasting machine, peanut peeling machine, coating machine, coated peanut roasting machine, seasoning machine, cooling machine, and packing machine. Here is a specific introduction to a 50kg/h peanut burger making machine. We also offer machines of other outputs.

Peanut coating machine overview

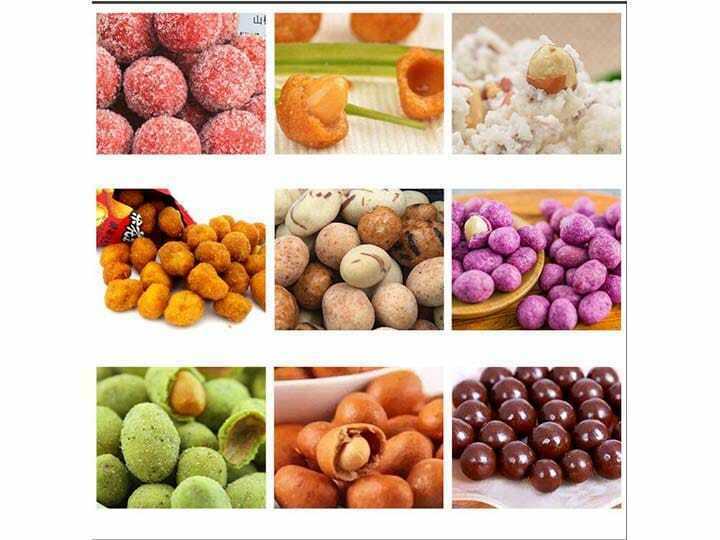

Application: candied nuts, coated groundnuts, chocolate-coated peanut, fish-skin peanuts, besan coated peanuts, toffee-coated peanuts, peanut burger, caramelized Peanuts, flour-coated peanut, green beans,

Production process: peanut roasting – peanut peeling – peanut coating – coated peanut roasting – cooling – seasoning – the packaging

Popular selling areas: Nigeria, Germany, India, Kenya, Australia, United States, and other places

Customization service: available

50kg/h coated peanut making machine advantage

The peanut coating machine is special equipment for coating peanuts and other nuts. The surface of the processed peanuts is smooth and meets the selling standards. The coating machine for peanuts has the characteristics of smooth movement, low noise, and no pollution. It can be used to make a great variety of popular granular snacks.

Coated peanut machine list

1. Peanut roasting machine: mainly used for roasting peanut, cashew nuts, chestnut, walnut, almond, beans, melon seeds, and other granular materials. Gas or electric heating can be chosen.

2. Peanut peeling machine: it adopts the method of rolling and peeling, which has the advantages of stable performance, long service life, good peeling effect, high productivity, and good quality. It is suitable for processing all kinds of peeled peanuts, almonds, and so on.

3. Coated peanut machine: Put the roasted peanut into the coated peanut making machine and the peanut will be combined with flour, sugar, or other addition uniformly.

4. Swing roaster machine: Plane rotary mixing style, using stainless steel. Peanut can get uniform heat, high capacity, low broken rate, pollution-free.

5. Cooling machine: It is combined with a variable speed drive device, cooling box, cooling fan. It has high output, no pollution, good effect.

6. Seasoning machine: the octagon flavoring machine can make peanut mix evenly in a short time and automatically discharge the peanuts.

7. Packing machine: suitable for packing granular products.

Parameter

| Machine Name | Parameter |

| Peanut Roaster | Capacity: 50kg/h Power:1.1kw Electric heating: 16kw Voltage:380V 50Hz Size: 1850*1200*1600mm |

| Dry peanut peeling machine | Peeling rate: over 96% Capacity: 200-250kg/h Size: 1100*400*1000mm |

| coated peanut making machine | Diameter: 1000mm Capacity: 30-45kg/batch Coating time: 1-2hour/ batch Power: 1.5kw Size: 1000*1000*1600mm Weight: 180kg |

| Swing roastermachine | Model: TZ-100 Capacity: 80-100kg/h Heating power: 25kw Swing Power: 0.75kw Size: 2.2*2*1.5m Weight: 500kg Working temperature:180-220℃ |

| Cooling box | Size: 1.3 * 0.6 * 0.6m Fan power: 1.1kw Voltage: 380v 50hz |

| Seasoning machine | Model: TZ-800 Capacity :300kg/h Power :1.1kw Size :1000*800*1300mm |

| Packing machine | Model: TZ-320 Bag style: back seal Packing speed: 32-72bag/min or 50-100 bag/min Bag length: 30-180mm Bag width: 25-145mm Filling range: 22-220ml Power: 1.8kw Size: 650*1050*1950mm Weight: 250kg |