Recently, Taizy factory exported a 400kg/h almond cracker machine to the USA for helping to shell all kinds of nuts, such as almonds, walnut, etc. The successful export of the almond cracker machine to the United States exemplifies Taizy’s commitment to providing tailored solutions that address specific client needs.

Client Profile for Almond Cracker Machine

Hailing from a small-scale nut processing facility in the United States, our client is engaged in the meticulous art of nut processing.

With a wide variety of nuts passing through their production line, they were in search of a solution that could enhance their efficiency and streamline their processes.

Specifically, they were interested in a commercial-grade machine that could efficiently crack and shell almonds, walnuts, and other nuts.

What does the American customer care about nut processing?

Our American client’s primary goal was to invest in a machine that could significantly increase their processing efficiency. Speeding up the nut cracking and shelling process was vital to meeting their production demands.

The client’s focus was particularly on almonds, as they are a widely consumed nut, often used in various food products, from snacks to baked goods.

While efficiency was a top concern, maintaining the integrity of the nuts during the cracking and shelling process was equally crucial.

The client emphasized the importance of intact almond kernels, as these intact nuts hold more value in the market due to their aesthetic appeal and ease of further processing.

Tailored Solutions for the Customer

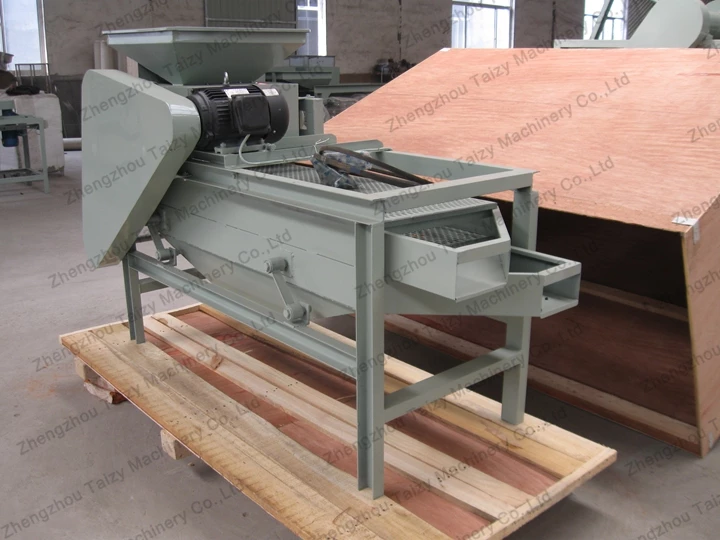

Understanding the client’s specific requirements, Taizy recommended a versatile and high-capacity almond cracker machine. With a processing capacity of 400kg/h, this machine was designed to efficiently crack and shell a variety of nuts, including almonds. The machine’s design took into consideration both the need for speed and the necessity to preserve the integrity of the nuts.

The proposed solution resonated with the client’s needs and objectives. The offered almond shell removing machine not only matched their demand for efficiency but also addressed their concern for preserving nut quality. The machine’s multifunctionality, capable of handling various nut types, provided them with versatility for their processing needs.

With the acquisition of the almond cracker machine, our American client is positioned to significantly boost their nut processing efficiency and maintain the quality of their products. The enhanced processing capacity of the machine ensures that they can meet market demand without compromising on nut integrity.

Commercial Almond Shell Removing Machine for Sale

By focusing on efficiency, quality preservation, and customization, we were able to deliver a machine that met and exceeded our client’s expectations. This partnership highlights the importance of understanding client requirements and offering solutions that drive productivity and growth in the nut processing industry.