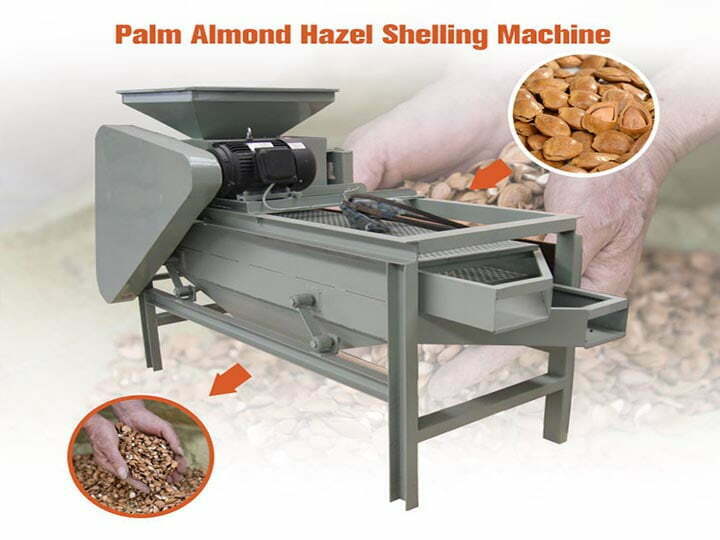

An almond shelling machine is to break the almond shells, often used in the almond cracking line and other nut processing industries. The almond sheller is suitable for shelling hard dry fruits such as almonds, palm kernels, hazelnuts, walnuts, pecans, Macadamia nuts, peach kernels, pine nuts, and badams.

The almond huller squeezes through two rollers to break the almond shell. The gap between the two rollers of the almond cracker machine can be adjusted to the size suitable for the material by handwheel. The almond shelling machine has a high shelling rate and low breakage rate.

How do almond shelling machines work?

The components of the almond sheller include a feed baffle, sheller roll, vibrating screens, feeder hopper, gravity separator, fans, etc. The almond cracker machine uses the chain to rotate and vibrate the raw materials. A support rod connects the vibrating screen with the frame. A special rubber sleeve is used at the connection, which has the characteristics of durability and shock absorption.

A baffle at the feed inlet can adjust the amount of feed. After the raw materials enter into the feed hopper, two side-by-side rollers begin to roll. The mutual rotation between the rollers squeezes the nuts so as to achieve the purpose of shelling. There are two layers of screens with large shells (or large kernels) on the top and small shells and kernels on the second layer.

Working video of nut sheller machine

Advantages of almond huller

- High productivity and shelling rate. The crushing rate can reach as high as 98%. The output ranges from 100-1000kg/h.

- High whole kernel rate and low breakage rate.

- Wide scope of application. Applicable to different types of nuts, including almond, walnut, hazelnut, palm kernel, pecan, Macadamia nut, badam, etc. There are handles on both sides of the almond shelling machine for adjustment, which can peel dry fruits of different specifications and diameters.

- Various modes and types of options. We offer almond cracking machines with different outputs. Our almond hulling machine has single-stage and three-stage types. Besides, we provide supporting equipment as well, including a lifting machine, an almond grading machine, almond kernels and shell separator, almond peeling machine.

- Food safety and no pollution. Almond sheller adopts pure physical shelling mode, which saves energy and environmental protection, ensuring food safety.

- Easy operation, safety, and durability. The almond hulling equipment is easy and safe to operate. It has a long service life.

- Space-saving and suitable for the production line.

Type 1: Single-stage almond shelling machine

A single-stage almond sheller is a shelling machine with a single level. It requires the adjustment of the gap between rollers according to the sizes of raw materials.

Through the vibrating screen, the first layer screens out large shells (or large kernels); the second layer vibrates the small shells and kernels, and the debris can be discharged from the bottom of the machine.

After the one-time break, there may be some small nuts that have not been broken. Then, it is needy to adjust the roller distance to re-break them.

Operation methods of almond sheller machine

- Adjust the spacing of the processing roller according to the size of the apricot kernel before operating the machine. The apricot kernel is broadly split into three tiers based on its flat size. The pressing roller gap must be 1-1.5mm less than the apricot kernel deviation size. To prevent the nuts from breaking, adjust the distance according to the physical raw materials.

- Start the machine.

- Before beginning large-scale processing, test the clearance of rollers with a modest number of almonds.

- After processing, stop the machine.

Technical data of almond shelling machines

In order to increase the yield, the almond sheller is usually used in conjunction with the almond sieving machine.

| Item & Picture | Parameters |

1. Cracking machine | Model: TZ-300 Capacity:300-400kg/h Power:2.2KW Voltage:220v/380v Size:2*1*1.45m Function: only crack shells |

2. Separating machine | Model: TZ-400 Capacity:300-400kg/h Power:2.2kw Voltage:50hz/380v Size:2.2*0.8*1.6m Function: separate Kernel and shell |

Type 2: Three-stage almond sheller

The three-stage almond huller machine can divide almonds, hazelnuts, peach kernels, etc. into three levels according to size, and the shelling can be completed at one time. The almond shell separating machine mainly contains a hopper hoist, adjustable rollers, a motor, and vibrating and discharging screens of three specifications. The almond shell remover integrates the functions of grading and shelling, which is very efficient and labor-saving.

Parameter of large type almond huller

| Model | Voltage | Power | Frequency | Yield | Shelling Rate | Dimension | Weight |

| TZ-1000 | 380v | 6.75kw | 50HZ | 1000kg/h | ≥98% | 3.2*2.1*2.6m | 2100kg |

Cautions in operation

- Pay attention to adjusting the gap of the roller reasonably to avoid breakage of large kernels. The gap of the pressing roller shall be 1-1.5mm smaller than the deviation size of the apricot kernel.

- Please adjust the bolts at both ends of the hoist at right time to avoid deviation and affect the working performance.

- All transmission parts, sprockets, and bearings of the almond shelling machine shall be lubricated regularly, and all bolts shall be checked and tightened regularly to ensure normal use.