The fully automatic peanut butter manufacturing line is an ideal solution for the continuous production of large quantities of peanut butter. The capacity of the peanut butter manufacturing equipment reaches 500kg-1000kg/h. Thus, the peanut butter processing line is suitable for medium or large peanut butter processing factories. The main equipment of the automatic peanut butter manufacturing line involves a continuous roasting & cooling machine, a peanut peeling and splitting machine, a peanut grinding machine, and a full-automatic peanut butter filling machine.

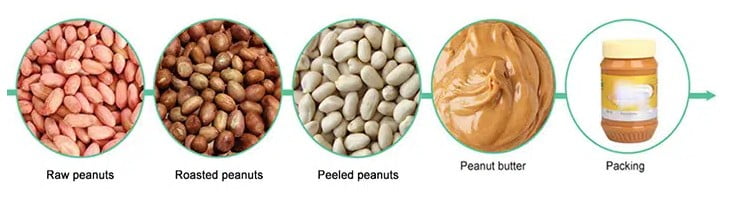

Peanut butter manufacturing process

The main peanut butter manufacturing process includes roasting and cooling, peeling, grinding, and filling.

1. Roasting and cooling

The continuous peanut roasting machine roasts the peanuts on the chainplate through hot air and then cools them down after roasting.

2. Peeling

The peanut peeling machine efficiently removes the red skins of peanuts and discharges the peeled peanut kernels.

3. Grinding

The peanut butter grinding machine is a combined peanut grinder in which the peanuts are well ground by friction, vibration, and other complex forces.

4. Filling

The automatic peanut butter filling machine has several filling heads, which fill the peanut butter with the same volume into various containers.

Features of automatic peanut butter manufacturing line

- High degree of automation: automac control and easy operation

- High productivity and continous production: output reaching 500-1000kg/h

- Super-fine peanut butter and natural flavor: The fineness is as high as 125-150meshes.

- Wide application: applicable to sesame butter, chilli sauce, cocoa paste, almond butter, etc.

- Customized service available

Main technical data

The following are the main parameter of major machines and supportive equipment in the peanut butter manufacturing line.

| Order number | All machine names | Power(kw) | Dimension(mm) | Weight(kg) |

| 1 | Hoist | 0.75 | 1600x750x3000 | 260 |

| 2 | Continuous roasting machine | 130 | 8500x1800x2600 | 3000 |

| 3 | Hoist | 0.75 | 900x750x3000 | 260 |

| 4 | Peanut peeling machine | 3 | 1900*800*1350 | 500 |

| 5 | Selection conveyor | 0.75 | 6000*800*1000 | 400 |

| 6 | Hoist | 0.75 | 900x750x3800 | 260 |

| 7 | Storage device | 0.04 | 1200x1100x3300 | 200 |

| 8 | Peanut grinder machine | 30×2 | 1400x1250x2000 | 1300 |

| 9 | Storage device | 1300x1300x900(500L) | 50 | |

| 10 | Mixing tank | 3 | 1000x1000x1900(500L) | 200 |

| 11 | Degassing tank | 3+1.5 | 900x900x2500(500L) | 300 |

| 12 | Pump | 1.5×3 | 1200x300x350 | 60×3 |

| 13 | Storage tank | 900x900x1200(500L) | 150 | |

| 14 | Filling machine | 0.8 | 2000*1100*1550mm | 300Kg |