This industrial deep frying machine is also called an automatic conveyor frying machine, widely used in the continuous production of fried nuts, meat, vegetables, pasta, and other products. With a high degree of automation, the automatic conveyor frying machine is often used in various production lines. This conveyor belt frying machine is labor-saving, oil-saving, and can keep unified product quality. As one of our popular products, the deep frying machine has been delivered to the Philippines, Thailand, South Africa, and many other countries. Here is an introduction of a recent case of deep frying machine Philippines.

Specificiation of commercial deep fryer philippines

We recently shipped a commercial batch frying machine to the Philippines. This customer chose the electric type machine with the capacity of 200kg/h. He intended to produce fried banana chips for sale and this model we recommend to him satisfied his need. After negotiating the machine details several times, we signed the contract. The following is part of the technical data of the deep frying machine Philippines.

Mesh Length: 2m

Size: 2200*1000*1800mm

Capacity: 200kg/h

Motor: 36kw

Heating resource: gas

Packaging display

Structure features of deep frying machine philippines

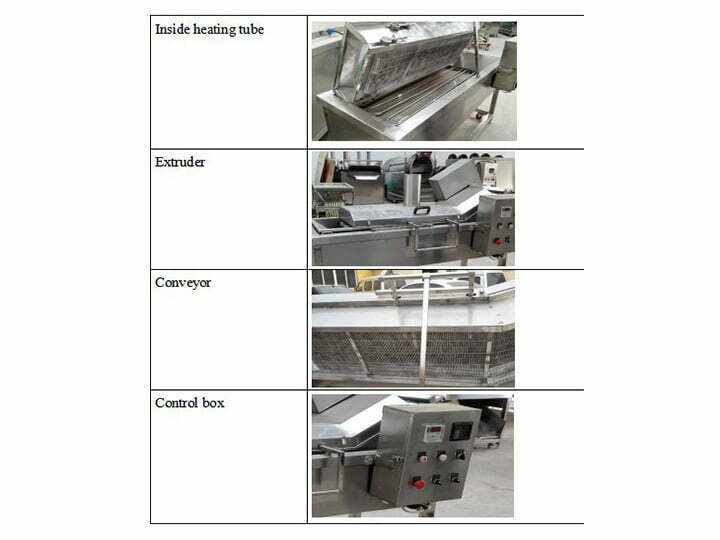

The deep frying machine mainly contains the frame, heating tubes, extruder, conveyor, control box.

- Mesh belt transmission adopts frequency conversion speed regulation, so the frying time is controllable.

- The adoption of high-efficiency heat conduction device realize high utilization rate of energy, and is conducive to reducing the production cost.

- The whole machine material is made of food grade 304 stainless steel.

- A slag discharge system is set at the bottom to discharge the generated residue at any time. The equipment is equipped with oil circulating filtration system to prolong the service life of oil. The automatic lifting system, upper cover and mesh belt, which can be lifted and lowered, are helpful for cleaning.

Advantages of the automatic conveyor frying machine in operation

The deep frying machine adopts advanced technology and shows many advantages over the traditional fryer machine. Because product debris and other frying by-products are removed in the process, it produces a good oil filtration effect and can reduce frying odor and free fatty acid content. In addition, in the continuous frying system, the conveyor frying machine does not cause much original heat loss, and the frying time is short. Moreover, because the conveyor belt frying machine allows setting the consistent frying temperature and time, it can ensure the constant product appearance and flavor, and optimize the product quality.