Peanut candy is a common snack that is favored by people in many countries. In the food processing industry, the peanut bar making machine (also known as the peanut brittle making machine) can realize a series of processing steps from raw peanut kernels to packed peanut candy. The main machine of the peanut candy bar production line is an all-in-one machine that can continuously spread, shape and cut. The peanut bar molding machine adopts frequency conversion adjustment, and the cutting size and molding degree are accurate. The whole peanut candy making machine is produced continuously and automatically, realizing truly automatic and intelligent operation. Let’s get to know more about how to make peanut brittle with the peanut candy manufacturing machine.

Peanut bar making machine introduction

Scope of application: peanut candy, sesame peanut candy, sunflower seed crisp, sesame crisp, and other foods.

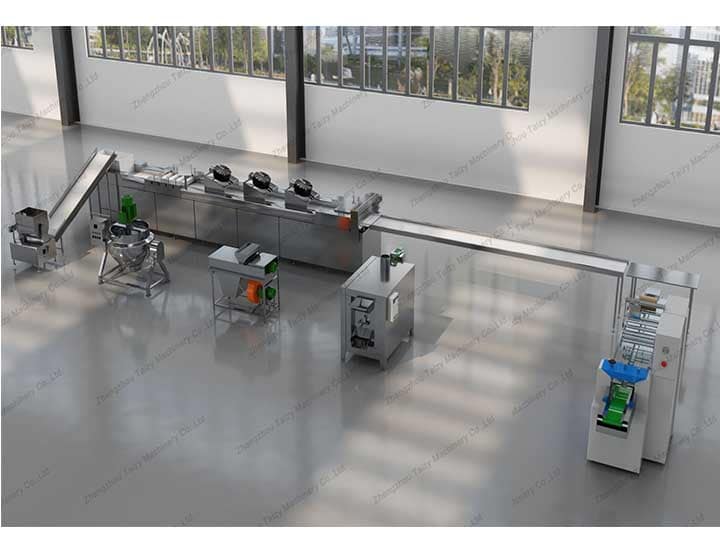

Equipment included: The peanut candy bar processing plant is composed of a peanut roasting machine, peeling machine, a sugar boiler, a mixer, a forming machine (flattening machine, cross-cutting machine, vertical cutting machine, cooling device), and other parts, and the production is automated.

General output: 300-1500kg/h

Equipment advantages:

- The size of the peanut candy produced can be adjusted to meet different needs.

- Mechanical kneading will not damage the nut particles, and the molding is beautiful; direct molding, no rework waste and loss.

- The peanut bar molding machine is mechanically driven, and the positioning is very accurate; the upper and lower molds are closely matched, and the molding effect is very good.

- Equipped with a high-performance inverter, convenient speed regulation, high efficiency; stable performance, and high-speed continuous production.

- The molds, hoppers, and other parts have been treated with anti-sticking.

- In the self-cooling conveying link, the length can be changed or a cooling fan can be installed as needed to improve the cooling effect.

- All parts that come into contact with food of the peanut bar making machine are made of food-grade stainless steel and are resistant to oil and high temperature.

Ingredients preparation and pre-processing of peanuts

Main ingredients: peanut kernels, sucrose, maltose, edible oil, etc.

(Note: As a peanut bar making machine manufacturer, we are able to provide detailed production formulas, technical training services, etc.)

Peanut processing:

- Put the peanuts in the peanut roaster and bake them until the peanuts are well roasted and then discharge them.

- Use a peanut peeling machine to remove the skin of the peanuts and then manually select them. The standard for selecting peanuts is that they are large and full, and there is no mildew.

Production process of peanut candy manufacturing machine

1. Boil sugar

Add the prepared sugar to the syrup cooking pot and start to heat. When boiling sugar, attention should be paid to stirring to avoid the phenomenon of sticking to the pot. When the temperature reaches 135 °C, due to the evaporation of water, the sugar solution forms a massecuite, the color is light yellow, and the filaments can be pulled. At this time, adding edible oil, the purpose is to make the product crispy and shiny. After stirring evenly, heat until the product temperature reaches 160°C.

2. Mixing syrup and peanuts

Pour the syrup and roasted peanuts into the mixer machine and blend quickly to mix the peanuts and sugar evenly and remove the trapped air.

3. Molding and cutting

Use the integrated peanut brittle forming and cutting machine to press and cut into pieces, and pay attention to adjusting the thickness in advance to ensure the expected specifications of peanut candy.

4. Packaging

An automatic packaging machine can complete automatic and accurate packaging.

If you would like to know more about the making of peanut brittle with the peanut bar making machine, please send us your specific requirements. We would like to hear from you.